Vape cartridges are extremely popular nowadays, and this article is created to introduce you to vape cartridges, expose what empty vape cartridges are composed of, and explain the process of making empty vape cartridges.

What Is a Vape Cartridge

A vape cartridge is a small attachment hooked onto a marijuana e-cigarette or vape pen. It is actually a vaporizer device containing a heating element used to atomize or vaporize CBD or THC vape oil. Usually, a vape cartridge comes with 510 threading, so that means, in order to utilize it correctly, you require a 510 thread battery.

There are two types of cartridges that emerge from the atomization core. One is ceramic core and the other is wick. The cotton of the wick has a better taste, but its downside is that it’s easy to burn. The chemical and physical properties and times of using ceramic core are a great deal better than those resulting from the use of cotton. Currently, the majority of the market carries ceramic core vape cartridges. They are what users most frequently ask for and what they are most likely to prefer if they’ve tried both.

What is an Empty Vape Cartridge

These are small containers that hold a vaping solution or a mixture. Refillable cartridges are basically not very expensive and in the long run will save you more money than using pre-filled cartridges or disposable CBD vape pens. Although oil cartridges are disposable, you can usually refill them and use them multiple times. The better the materials they are made from, the more times you can reuse them.

Compositions of Empty Vape Cartridges

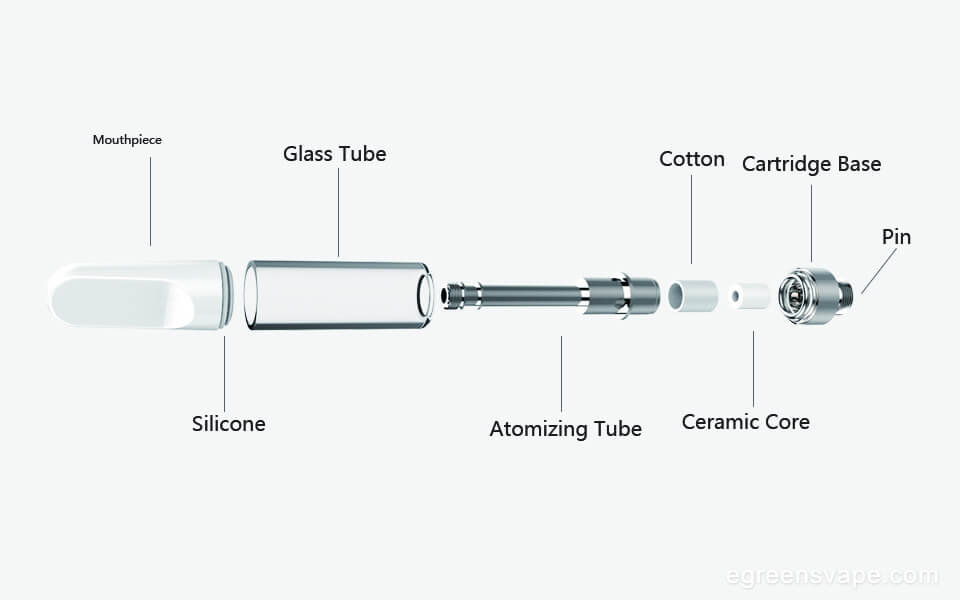

Different parts compose a vape cartridge. Take, for instance, a Ccell vape cartridge.

This type of cartridge is made of a ceramic mouthpiece, a Silica Gel mouthpiece, a glass tube, an atomizing metal tube, a Silica Gel that’s oil-proof, a ceramic core, cotton, a metal base, and an electrode pin, etc. You might think that it’s an easy matter to assemble these parts into a vape cartridge, but it requires great precision. If there is even a small mistake, it will lead to problems, such as leaking oil. That’s why before these cartridges are assembled, it’s necessary to inspect the size of each part, whether it has the ability to withstand use and to ensure that the parameters of the atomizing core are okay. Thus it is necessary to use high quality parts to produce empty vape cartridges.

We highly value our reputation for producing quality products and stress this throughout the production process.

How An Empty Vape Cartridge is Made

Explaining clearly how the parts of vape cartridges are made is not easy to do. We shall try to make it simple to understand.

Mouthpiece — Normally, the mouthpieces used for a vape cartridge are ceramic, plastic, and metal. Plastic and ceramic mouthpieces are made by using a mold. That’s the reason why when you use a customized cartridge you may have to pay mold fees. By using an automatic lathe it is easy to make a metal mouthpiece, taking only 5-7 days. It’s different for a mold for a ceramic or plastic mouthpiece, because these can take 3-4 weeks.

Silicones — All of the silicones used in a vape tank are created by using a mold. A silicone mold can take 2-3 weeks to produce.

Atomizing Tube — It takes an automatic lathe to make the metal atomizing tube. Most cartridges use a brass atomizing tube, while some of the cheapest are made from zinc alloy. Stainless steel can be employed when a lead free cartridge is needed.

Ceramic Core — A mold is required to make a ceramic core. Normally, a ceramic core is cylindrical, but some are T-shaped and pad shaped. The heating element is made from a combination of porous ceramic and nickel heating coil.

Cartridge Base — An automatic lathe is used to make the base for metal cartridges. Its job is to hold the atomizing tube and glass in place. It is clearly visible that there are several airflow holes on the bottom of the airflow cartridges. Some of these have 2 holes and some have 4 holes. Furthermore, the 510 thread is on the base, used to connect 510 batteries.

Electrode Pin — These are normally composed of brass and then plated with chrome or gold. The main job of the electrode is to move the electricity along, and some electrodes have small holes which are used airflow. If there is a small hole located in the electrode pin of your vape cartridge, that means it can be used with an automatic battery, for example, a Ccell M3 battery. Not all vape cartridges are made this way, so you have to check carefully if this is what you intend to do.

How Are Empty Vape Cartridges Made/Assembled

Here is the assembly of vaping cartridges broken down into 4 steps to make it easy to understand.

Step 1 — Assemble the ceramic coil into the atomizing tube

Step 2 — Take the atomizing tube and the glass tube and assemble them on the base of the cartridge

Step 3 — Place the electron pin in the base from the bottom, snipping the extra heating wire.

Step 4 — Screw the ceramic mouthpiece on

Once the empty vape cartridges are put together, they must still be inspected and tested with the use of special tools, for things like testing the resistance. Even though they have been tested before you purchase them, there is still a defect for these empty vape cartridges. This is a widely known and accepted fact. We try our best to lower the defect rate as much as we possibly can and to keep it below 0.5%. However, it is still possible that you will end up buying a defective cartridge.

There have been serious safety and health issues connected with vaping technology in the recent past. This means that vape cartridges manufacturers and retailers have to be extra cautious and their products and where their products are made. It’s not enough for the users to play it safe, but the manufacturers and retailers have to as well. And you can rest assured that we do. Quality is important to us and an essential part of every item we produce. We adhere to the highest standards because we respect our customers.